Why Choose a Geomembrane Welding Machine for Your Projects?

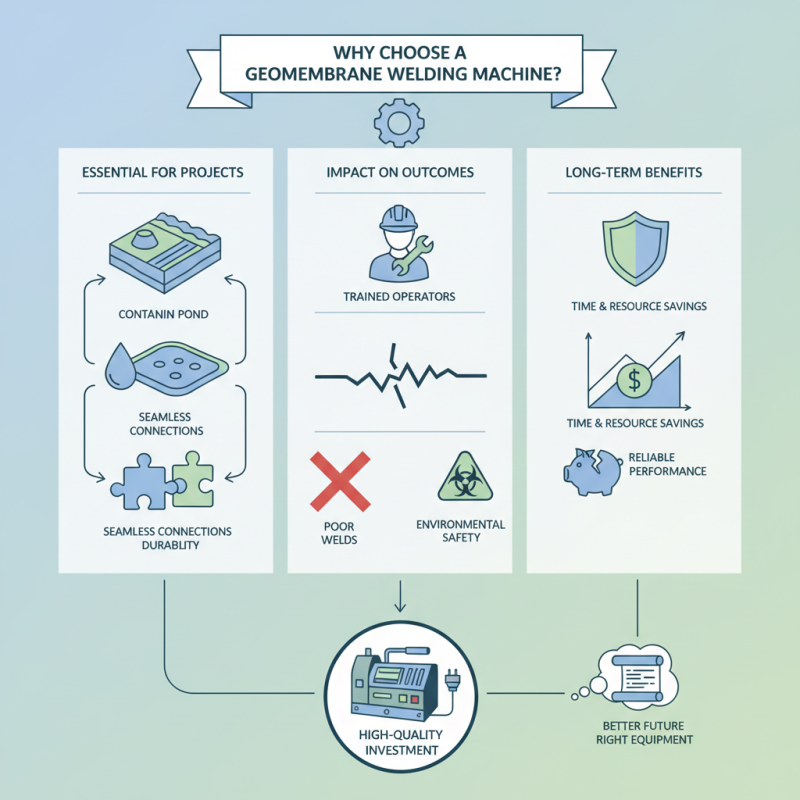

In today’s construction and environmental projects, a geomembrane welding machine is essential. This equipment is crucial for applications like landfill liners and water containment. Its role in ensuring seamless connections and durability cannot be overstated.

Choosing the right geomembrane welding machine can significantly affect project outcomes. For instance, operators must be well-trained. They need skills to handle equipment effectively. Often, users overlook the importance of quality welding. Incomplete or poor welds lead to costly repairs. This is not just about efficiency; it impacts environmental safety as well.

Investing in a high-quality geomembrane welding machine can save time and resources. While it requires initial costs, the long-term benefits are evident. However, many companies take shortcuts, leading to unreliable performance. Reflecting on past projects can guide better decisions in the future. The right equipment can make all the difference.

Benefits of Using Geomembrane Welding Machines in Construction Projects

Geomembrane welding machines are a crucial tool in modern construction projects. These machines offer durability and efficiency, especially for large-scale applications. They create strong seams, which are essential for preventing leaks in containment systems. This is particularly important in construction areas dealing with waste management or water reservoirs. The precision of these machines reduces the time spent on repairs.

Another significant benefit is their versatility. Geomembrane welding machines can work with a variety of geomembrane materials. This adaptability makes them valuable on different job sites. However, operators must be trained to ensure quality welding. Mistakes can lead to costly repairs. Sometimes, the results are not perfect, requiring extra checks. It’s a constant learning process to refine skills and improve outcomes.

Moreover, these machines can be operated efficiently in various weather conditions. They reduce the dependency on manual labor, which can slow down projects. However, they may require maintenance and calibration to function optimally. In some cases, operators might overlook minor issues, which can lead to failure. Reflecting on these challenges fosters a better understanding of best practices in geomembrane applications.

Key Features to Look for in Geomembrane Welding Equipment

When selecting a geomembrane welding machine, several key features are essential for successful projects. Quality heating elements ensure consistent temperature across the welding surface. According to industry reports, machines with precise temperature control lead to a 30% reduction in defect rates during deployment. This is critical for applications such as landfill liners and water retention systems.

Durability is another significant factor. A robust construction can withstand harsh environments. Studies show that equipment longevity correlates directly with project uptime. A well-designed machine should resist wear and tear, protecting your investment. Ease of transport and setup further enhances convenience on worksites.

Lastly, look for advanced control systems that allow real-time monitoring. These features enable operators to adjust parameters instantly, reducing the chances for human error. In fact, a report from the American Welding Society indicates that machines with automated controls improve welding speed by up to 25%. This efficiency can make a tangible difference in project timelines. However, always consider training needs, as high-tech machines may require operators to adapt quickly. A balance between technology and ease of use is crucial.

Comparative Analysis: Manual vs. Automated Geomembrane Welding Methods

When it comes to geomembrane welding, choosing the right method is crucial. Manual welding offers flexibility. Operators can adapt to different job sites and conditions. However, this approach can lead to inconsistencies. A skilled worker might produce excellent seams, while a novice may not deliver the same quality. Moreover, environmental factors like wind can impact manual welding.

On the other hand, automated geomembrane welding machines provide uniformity and speed. These machines can maintain precise temperatures and pressure levels. This consistency minimizes human error. However, they require a significant upfront investment. If the project scope is small, this may not be cost-effective. The learning curve associated with automated equipment can also be steep.

In practical applications, the choice depends on the project's needs. If quality and efficiency are priorities, automated solutions might be the way to go. For smaller, less complex projects, manual methods might suffice. Both options have merits and drawbacks. It's important to weigh these factors carefully before making a decision.

Why Choose a Geomembrane Welding Machine for Your Projects? - Comparative Analysis: Manual vs. Automated Geomembrane Welding Methods

| Aspect | Manual Welding | Automated Welding |

|---|---|---|

| Speed | Moderate | High |

| Skill Requirement | High | Low |

| Quality Consistency | Variable | High |

| Initial Cost | Low | High |

| Long-term Efficiency | Low | High |

| Portability | High | Moderate |

| Setup Time | Quick | Lengthy |

Application Areas Where Geomembrane Welding Machines Excel

Geomembrane welding machines are essential in various industries. They excel in applications such as landfills, mining, and water containment. These machines create strong, waterproof seals that withstand harsh conditions. In landfills, they are vital for environmental protection. Properly welded geomembrane liners prevent leachate from contaminating groundwater. In mining, they help secure tailings and protect the environment.

Water containment projects also benefit significantly from geomembrane welding machines. They ensure that water reservoirs and canals remain leakproof. This reliability is crucial for agricultural irrigation and industrial use. Using these machines can enhance efficiency and reduce water loss. However, challenges may arise. Operators may face difficulties with inconsistent welding temperatures. Ensuring the right settings can require practice and attention.

**Tips:** Regular maintenance of welding machines is essential. Keep the equipment clean and check calibration frequently. This practice can prevent malfunctions during critical projects. Training for operators should be a priority too. Skilled operators will achieve better results with less waste and more durability. Choosing the right machine for specific tasks can be tricky but pays off in the long run.

Maintenance Tips for Prolonging the Life of Your Welding Machine

Maintaining a geomembrane welding machine is crucial for longevity and efficiency. Regular maintenance can prevent costly repairs and downtime. According to a recent industry report, over 30% of welding machine failures are due to lack of maintenance. Keeping your equipment clean can make a big difference. Dust and debris can clog components, leading to overheating and reduced performance.

Inspecting the machine regularly is vital. Look for signs of wear on the welding tips and cables. Use a torque wrench to ensure all bolts are tightened appropriately. A study found that machines with regular inspections last up to 25% longer than those without. Tool maintenance doesn't stop here. Lubrication is also key. Insufficient lubrication can lead to component friction.

Don't forget the documentation. Keeping track of maintenance and repairs helps identify patterns. You can adapt your maintenance routine based on data trends. However, many operators overlook this critical step. Relying solely on intuition can lead to mistakes. Staying organized is essential for effective machine management.